by Jason Dewar, Vaetrix

What is Timed Test Mode?

Timed Test Mode is a new Main Menu Option added to our firmware which allows the customer to pre-set the period of time they want the gauge to record prior to beginning their test. Prior to the start of their test, the customer will be able to dictate the length of time the gauge will record at any interval between 1 minute and 24 hours. Once Timed Test is set, the gauge will log pressure for the predetermined period of time, then auto shut-off, preventing the customer from having to manually “stop/end” the recording session. The end result displays the Start Time/Pressure, Leak Rate, and End Time/Pressure all on one screen.

Why Did Vaetrix Create Timed Test Mode?

Historically, in residential gas service testing, technicians were required to perform pressure integrity tests at the main distribution line as well as at the residential service line itself. While the main line tests could last 4-8 hours, the service tests at the residence may only last 10 minutes and typically do not require temperature records. Technicians were manually recording the start pressure, waiting ten minutes, then manually recording the end pressure to document their test for record. How did they accomplish documenting this test in a quantifiable way with a time stamp? CELL PHONE PICTURES! They took a picture of the gauge pressure at the start with a time stamp, and then a picture after 10 minutes with the end pressure and a time stamp. They then uploaded the pictures in their final report for proof.

THE PROBLEMS: (1) Remembering to check the gauge at exactly ten-minutes from the start time in order for the test to be valid; (2) No record or proof any leakage between the ten-minute time period unless watching the gauge the entire test. (3) No recordable record for proof of the test being properly performed, heavy reliance on cell phone pictures, times and word of technician – no data points.

Vaetrix Solution and Industry Impact

Problem (1) Remembering to check the gauge at exactly ten-minutes from the start time in order for the test to be valid.

SOLUTION – Timed Test mode stops the log for you at the EXACT time frame required. This keeps the test time frame valid.

Problem (2): No record or proof any leakage between the ten-minute time period unless watching the gauge the entire test.

SOLUTION – Timed Test mode displays the leak rate on the screen in real time as well as at the end of the test to ensure there were no significant leak events missed.

Problem (3): No recordable record for proof of the test being properly performed, heavy reliance on cell phone pictures, times and word of technician – no data points.

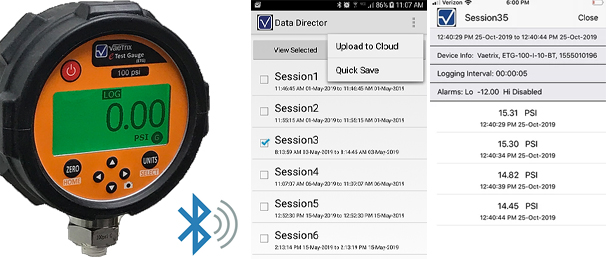

SOLUTION – Timed Test records the data points just like any other test log and it can be extracted and viewed in our software for hard proof of test validity.

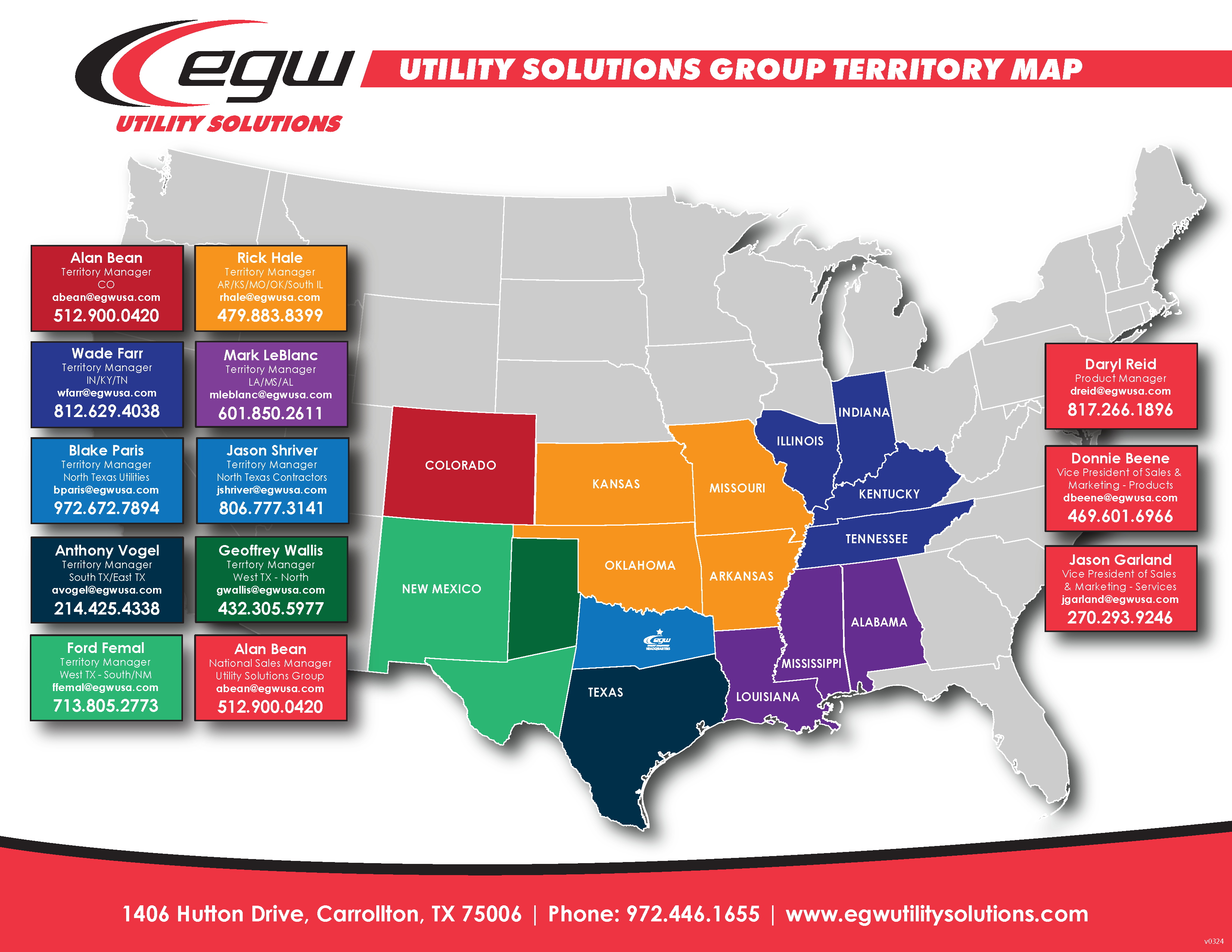

BONUS IMPACT: Timed Test logs/Screen can be easily uploaded into GPS and Scada Systems. The industry is beginning to require that pressure integrity tests tie directly into GPS tracking systems that monitor the safety/operating standards of that particular section of pipe. These programs store that pipe’s geographic location, integrity test records and distribution/consumption data. By pinpointing these pipes on the system’s grid, they can gather valuable information make informed decisions on how the grid distributes products safely and effectively.