by Reduct

What is Gyroscopic Pipeline Mapping?

Gyroscopic pipeline mapping is a technique used within the utility pipeline construction and survey sectors to provide 3D geographical information on underground utility pipes and ducts.

As an autonomous Orientation Measurement Unit (OMU) passes through a pipe or duct, a range of inertial sensors captures its change in heading, inclination, and acceleration at high frequency.

The resulting 3D profile links to the pipe segment’s start and endpoint coordinates, and an as-built map is created, which can be immediately uploaded into any GIS platform.

Gyroscopic mapping of underground utility pipes uses:

• Damage prevention The lack of underground utility data is a significant cause of pipeline damage, injuries, death, environmental damage, and delays during civil engineering projects. Gyroscopic mapping of underground utilities improves the data quality of utility survey records.

• Stress analysis Pressurized pipes typically must adhere to minimum bend radius specifications. Thanks to the high-frequency sampling rate, the standard bend radius calculation feature in the Reduct gyroscopic mapping solutions instantly yields highly accurate bend radius information.

• Flow management in gravity sewer systems As the name suggests, gravity is used in most sewers, and deformations resulting in localized sagging could lead to clogging of the pipe over time. That is why an inclination assessment of newly installed sewer systems before contractor handover or at periodic intervals of existing sewer systems is essential for optimal network management.

• Maintenance planning As policy demands, all utilities must be maintained and inspected periodically. However, the level of maintenance required may vary depending on the pipe’s condition or the soil surrounding it.

Sometimes a pipe can traverse several types of soil or is situated in an earthquake-prone area. Through periodic mapping, you can detect changes in pipeline subsidence at an early stage and redirect maintenance dollars to those areas where pipe movement is most severe.

Benefits of gyroscopic mapping technology

• Does not require aboveground tracing or tracking Gyro-mapping tools operate autonomously between entry and exit points.

• Can map at any depth Because tracing or tracking is not necessary, the probe can map deep-laying pipes, pipes crossing underneath rivers, highways, train tracks, or buildings with ease.

• Unaffected by groundwater level and electromagnetic interference A significant advantage over other types of locating technologies.

• Takes less than one hour to perform measurement Once the unit has run through the pipe four times, you can analyze the data on-site by uploading it to the field laptop.

• Samples at high frequency At 100Hz (100 samples per second), gyro mapping creates a very rich data set from which accurate and highly detailed positional and bend radius information can be derived.

When is the best moment to gyro-map underground utilities?

• Right after installation Mapping a pipe immediately after installation is the most cost-efficient moment in a pipe’s life cycle to obtain an accurate as-built. Besides the value as an independent technology to verify the contractor’s performance, it will also help protect your pipe from 3rd party damage during its remaining operational lifetime.

• Temporarily decommissioned utility pipes For existing pipelines with questionable as-built data, the best moment to map is during shutdowns for maintenance or repairs. The highly efficient operational procedures of gyro-mapping systems mean that the incremental shutdown time is minimal. Typically, you can map a 500m section of pipe in less than one hour.

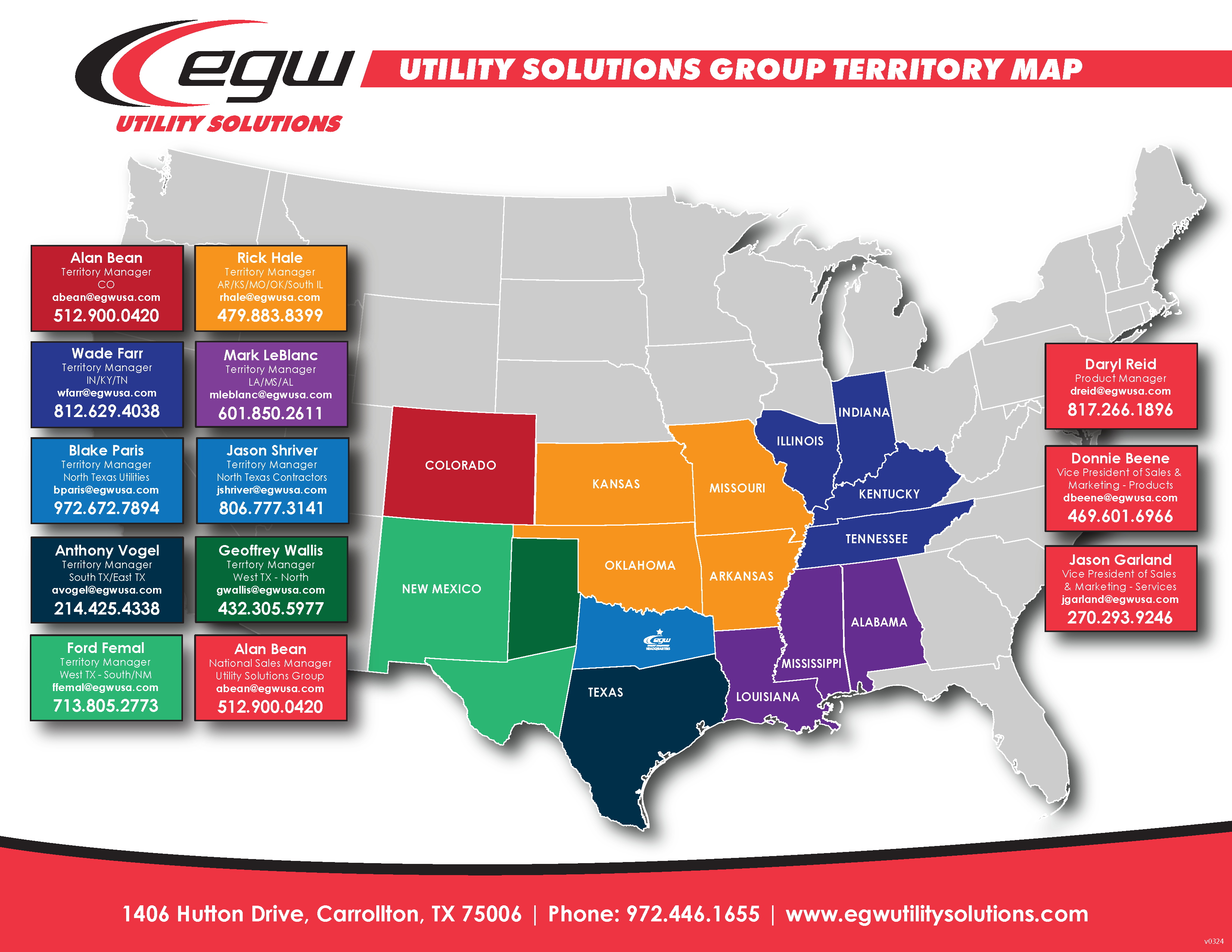

To learn more, visit www.egwutilitysolutions.com/reduct.

Don’t take the risk, get it mapped!